Liutaio

Consulting and Engineering Services

|

|

|

|

|

|

|||||||

|

FS |

Functional Safety |

Functional Safety Training |

|

|

||

Why is important a Functional Safety Training ?

If you are working on or

managing an Industrial Workplace, and you are interested in

keeping such process in production as long as possible, having insurance

support in case of eventualities, so, you are interested in applying FUNCTIONAL

SAFETY.

FUNCTIONAL SAFETY is the

methodology that leads the design, construction, and operation of an Industrial

Workplace, protecting people, equipment, and work environments from

harm.

Industrial Workplaces use

powerful machines and automated systems, which can expose operators to severe

safety risk.

This training course main goal is

To aim engineers who work

for:

·

Engineering companies in the design, selection,

installation, and commissioning of a (SIS) Safety Instrumented Systems

·

End-user’ companies who own and/or operate a process plant.

The course is not intended

for engineers involved in the design of internal hardware for logic solver

systems or for the design of field device components by OEMs.

The course is prepared to

provide participants with a view of the entire safety lifecycle from the user’s

point of view, as part of preparation for a (FS) Functional Safety engineer

certification.

Learning goals

1.

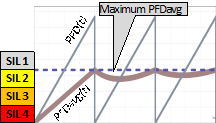

To understand the physical meaning of SIL rating.

2.

Review of IEC-61511 and IEC-61508 standard, applied in a

process plant.

3.

To understand SIL determination and SIL verification

processes

4.

Meaning and structure of a (SIF) Safety Instrumented

Functions.

5.

Verify if the design or implementation of a SIF satisfies a

required SIL rating.

6.

To understand and Review a SIL certificate.

Course Outline

|

Topic

description |

Module No. |

||||||

|

1 |

2 |

3 |

|||||

|

DAY 1 |

Introduction |

||||||

|

1.

|

Physical

meaning of “Probability”. |

ü |

ü |

ü |

|||

|

2.

|

Probability

of Failure of a (SIF) Safety Instrumented Function. |

ü |

ü |

ü |

|||

|

3.

|

Difference

between “Average Probability” and “Punctual Probability”. |

ü |

ü |

ü |

|||

|

4.

|

Relationship

between SIL rating and (PFDavg) “Average Probability of Failure on Demand”. |

ü |

ü |

ü |

|||

|

5.

|

SIL

rating order of magnitude. |

ü |

ü |

ü |

|||

|

6.

|

Is

a SIF component suitable for SIL “X”? |

ü |

ü |

ü |

|||

|

7.

|

Overall

Safety Life Cycle. |

ü |

ü |

ü |

|||

|

8.

|

Brief

description of methods for SIL determination and SIL verification. |

ü |

ü |

ü |

|||

|

9.

|

Risk

Reduction Factor (RRF). |

ü |

ü |

ü |

|||

|

10.

|

Layers

of protection. |

ü |

ü |

ü |

|||

|

11.

|

SIL

rating and RRF relationship. |

ü |

ü |

ü |

|||

|

DAY 2 |

SIL verification, and Safety Channel Architecture

(SCA) |

||||||

|

|

Safety Life Cycle.

Realization Phase. PFD Calculation. SIL Verification |

||||||

|

12.

|

Differences

between LOW and HIGH demand mode. |

|

ü |

ü |

|||

|

13.

|

Failure

Model |

|

ü |

ü |

|||

|

14.

|

Basic

SIF’s structure |

|

ü |

ü |

|||

|

|

Safety Channel

Architectures (SCA). |

||||||

|

15.

|

Single

Elements in Series |

|

ü |

ü |

|||

|

16.

|

XooN,

or XooN-M SCA |

|

ü |

ü |

|||

|

17.

|

Identify

which is the SCA in use in typical instrument arrangements. |

|

ü |

ü |

|||

|

18.

|

SCA

order of magnitude for selection in a SIF design. |

|

ü |

ü |

|||

|

19.

|

Effect

of Maintenance Philosophy on PFD calculations |

|

ü |

ü |

|||

|

DAY 3 |

Common Cause Failure and Maintenance, PFD

calculation shortcut and Examples |

||||||

|

|

SIF analysis |

||||||

|

20.

|

Identify

which are the SCAs in use in a SIF design, or implementation |

|

|

ü |

|||

|

21.

|

Identify

when to calculate PFD, and when to calculate PFDavg. |

|

|

ü |

|||

|

|

How to estimate

Common Cause Failure (CCF) |

||||||

|

22.

|

Common

Cause Failure (CCF) definition. |

|

|

ü |

|||

|

23.

|

Difference

between CCF and Common Mode Failure (CMF). |

|

|

ü |

|||

|

24.

|

How

to estimate the CCF effect in a SCA? |

|

|

ü |

|||

|

25.

|

Identify

where CCF effect appears in a Safety instrumented implementation. |

|

|

ü |

|||

|

DAY 4 |

Apply the PFD calculation shortcut to verify SIL |

||||||

|

26.

|

Example

01 - SIF with 2oo3 voting logic at transmitters. |

|

|

ü |

|||

|

27.

|

Example

02 - 3oo4 safety logic, let down station at the end of an offshore pipeline. |

|

|

ü |

|||

|

28.

|

Example

03 - HIPS SIF with 2oo3 @ Transmitters, and two safety valves. |

|

|

ü |

|||

Methodology

This is an instructor led

course with interactive classroom discussions and practical examples of

implementation of safety systems, and SIL rating calculation.

Course Fees and Schedule

Course fees are calculated

upon Client formal request to: services@LiutioCES.com

Calculated fees depend on:

·

Client selected course module: 1, 2 or 3.

·

Number of participants.

·

Selected method to provide training. See Q&A section

below.

·

Liutaio calculation tools are used during the course for

demonstration purposes, but those tools are not included in the course delivery

items.

Q&A

How will LIUTAIO provide training?

Choice 1 – Remote Meeting

via ZOOM.

Choice 2 – Remote meeting

using Client facilities.

Choice 3 – Client pays all

travel/Living expenses to allow LIUTAIO representative to provide training

services at Client location.

What does functional safety help in improving?

Functional safety focuses on

those aspects that improve safety, detect faults and control failure — i.e.,

minimize uncertainty. Let us dig deeper to understand the two types of fault

coverage and the hardware element classification.

Who is responsible for functional safety?

The workplace or

project manager is the one responsible for ensuring that the project

reaches its goals. This includes all functional safety goals for any project to

which functional safety requirements apply. The project manager is authorized

to request resources from the organization.

What is an example of a functional safety concept?

For example: In

an airbag system, the safety goal is that "Airbags should only be deployed

during a collision more than 2g". In this example, the

sensing system to determine the impact of the collision should be responsible

for this safety goal.

What is the difference between safety and functional

safety?

Insulation to protect the

system against high temperatures is a safety measure but not a functional

safety measure. Both may prevent fire. Now let us work through a further

example in more detail. Functional safety inherently means the safe

operation of a product during its primary function.

What are safety goals and objectives?

The goals and objectives

should focus

on specific actions to improve workplace safety and health. To

establish goals, management should: Establish realistic goals for improving

safety and health. Goals emphasizing injury and illness prevention should be

included rather than focusing on injury and illness rates.