PC

Process Control

I

Instrumentation

S

Simulation

FS

Functional Safety

Functional Safety Services

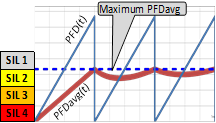

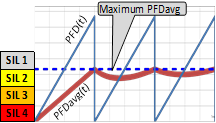

- SIL verification of Low and High demand (or Continuous), for new or existing safety systems (per Safety Instrumented Function, SIF, or whole system).

- SIL sensitivity design analysis, in order to review/optimize selected safety components/instruments, SIF implementation, selected proof test periods, or applied maintenance philosophy. Target: to identify design bottlenecks, and to provide recommendations to reach target SIL rating with minimum re-design effort.

- Chairman for HAZID, PHA, LOPA, HAZOP and SIL determination assessments.

- Chairman for FMEA, FMECA and FMEDA assessments.

- Determination of safety devices, equipment or system “Failure Rates”, “SIL Certification” and manufacturing/configuration improvement recommendations from FMEDA assessment.

- Development of Design specifications, or Safety Requirements Specifications (SRS) for safety systems.

- Auditory of existing or under design safety systems (Whole system, or per SIF basis)

- Basic training on IEC-61608 (IEC-61511).

- Training on IEC-61608 (IEC-61511) to increase participants capabilities to understand and to review “SIL Certificates”, and “SIL Verification” reports.

- Coaching and mentoring on “Functional Safety”.

- Review safeguarding systems VENDOR’s implementation.

- Perform FAT and/or SAT of safeguarding systems, following design requirements.

- Develop Cause and Effect tables (C&E).

- Review design/facilities for “Maintenance Override Switches” (MOS) and proof test in safeguarding systems.

- Design and/or review implementation of “Valve Full/Partial Stroke Test”.

- Design and/or review Safeguarding narrative.

- Design and/or review proper integration of Control and Safeguarding narrative.

- Design and/or review safety sequences, integrated with “Cause & Effects” (C&E) tables and process design.