PC

Process Control

I

Instrumentation

S

Simulation

FS

Functional Safety

Process Control Services

1. "Professional Tuning Service" for PID industrial controllers

THE WAY TO MAKE CONTROLLERS TO WORK AND PERFORM.

--- No Guessing. No Trial-And-Error.

>>>> No Specialized software required.

RESULTS:

======== No Oscillations. No Overshoot.

-------------- GUARANTEED soft Take-Off and soft Landing.

-------------- GUARANTEED disturbance rejection.

For evidence, refer to: (PDF)

0125B10PL02 Rev.01 Evidence of Effective tuning for PID industrial controllers

Contact us for further information

THE WAY TO MAKE CONTROLLERS TO WORK AND PERFORM.

--- No Guessing. No Trial-And-Error.

>>>> No Specialized software required.

RESULTS:

======== No Oscillations. No Overshoot.

-------------- GUARANTEED soft Take-Off and soft Landing.

-------------- GUARANTEED disturbance rejection.

For evidence, refer to: (PDF)

0125B10PL02 Rev.01 Evidence of Effective tuning for PID industrial controllers

Contact us for further information

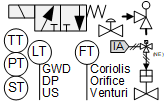

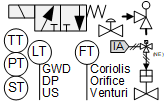

- Control loop tuning for compressors, turbines, boilers, separators, columns, exchangers, heaters, boilers etc. Including Control loop configuration review, and Tuning report.

- Design/Review of APC, Complex or Regulatory control loops.

- Design/Review of Compressors’ control (Load/Anti-Surge), Distillation control, Combustion/Incineration control, Reactor control, Boilers’ Load/Distribution control (2-3 elements), Serial or parallel arrangement, Load sharing, Production/Injection wells control.

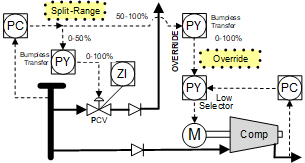

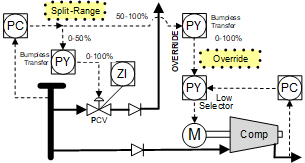

- Design review Cascade control, Ratio control, Split range control, Constraint control, Feedforward, Batch control, Distillation control, Control Loops’ Bumpless Transfer, Heat control, control calculations.

- Development of Process Control narratives document(s).

- Involvement and Participation on Control and safeguarding systems FAT and/or SAT, in order to verify compliance with design documents, proper configuration and performance.

- Design/Review logic sequence for plant/equipment startup, several operation modes, shutdown and maintenance mode.

- Application of optimization techniques based on MPC (Multivariable Predictive Controller) and/or Linear programming.

- Integration between Process Control and Safeguarding design and operation, of control loops and logic sequences.

- Data application integration between analyzers, Laboratory, Advance/Complex control strategies, Neural network models.

- Development of advance Tank monitoring based on ASTM-1250 (API MPMS 11).

- Development of “Simple Dynamic Plant Models” (SDPM) for testing control loops and/or equipment logic sequences.

- Development of templates to simplify Operation/Maintenance and to normalize Control/Safeguarding operation/Configuration of plant equipment like tanks, pumps, air coolers, control loops, wells, compressors, etc.

- @ Construction/Commissioning/Startup: Process control support.

- Issues on Control loops, configuration, HMI, sequence logic, package integration review, de-bottlenecking and resolution.